M.0118

Sailing

“A bucket in the endless distribution chain that creeps across the world”

A car journey doesn’t take very long, a few hours at most. A train journey likewise. But a sea voyage is a different matter: the ship may be away for days or weeks on a course that takes it far from civilisation. When they step on board, the passengers and crew cross an invisible line, leaving the familiar world behind for another one that operates on a different time scale and follows different rules. The crew form a hierarchical community bound by loyalties and conventions peculiar to seafarers. And while the days may pass slowly, time is important: the captain is under pressure to minimise costs and keep to schedule, regardless of weather conditions that can make handling a vessel difficult, unpleasant, and occasionally dangerous. In this last Section, we’ll be looking at the crew rather than the vessel as such, the conditions under which they work, some of the tasks they perform, and how they manage the vessel and its cargo.

Passengers and crew

So who is in charge? The ship’s master has overall command and is ultimately responsible for the ship and its contents. He or she is called ‘captain’ and has a supporting team, in order of seniority the first mate (otherwise known as the chief officer), the second mate, who is responsible for navigation, and possibly others depending on the size of the vessel. The master in turn receives instructions from the operating company. There’s a lot of paperwork involved. The master is accountable for company assets – the vessel, its passengers and its cargo – together with running costs, and will document progress to reassure the owners and shareholders that their interests are in good hands. The running costs mount up during a voyage: a container vessel may burn over a hundred tonnes of fuel a day, and depending on its size, the toll for a single passage through the Suez Canal may exceed a quarter of a million US dollars.

The crew’s duties

Duties routinely performed by the crew can be broken down into three areas. The first consists of ‘deck duties’, looking after the ship and its cargo. The second is concerned with the ship’s engines, and the third with the needs of the passengers and crew. On a large vessel, each will be carried out by a separate body of personnel.

Deck duties are controlled from the bridge, the conning position that houses the ship’s helm and navigation gear. This is the province of the captain together with the first and second officers, who are responsible for ensuring a safe passage. This entails supervising a range of tasks: keeping a lookout, navigation, manoeuvring, managing the cargo, handling anchors and mooring lines, checking emergency equipment, and generally maintaining the ship in good condition. The captain can’t supervise them personally, at least not all the time, so the day is divided into watches, each being covered by a senior officer nominated as Officer of the Watch (OOW) acting on the master’s behalf. Systems vary, but the standard procedure for a merchant vessel is to divide the 24-hour day into six ‘watches’, each of four hours duration.

While on watch, the OOW is responsible for the ship and all on board. From time to time he or she may need to change course or supervise a manoeuvre. Even though the auto-pilot is switched on, the depth-sounding equipment is working, and the radar system will track other vessels automatically and give warning if there is a risk of collision, the OOW will keep watch throughout. The reason is that the instruments don’t give a complete picture of what is going on around the ship. The depth-sounder indicates how much water there is underneath the hull, but it can’t detect submerged rocks or sandbanks that might lie ahead, and the radar may fail to pick up a small boat in the vessel’s path. Scanning the sea for long periods calls for a good deal of concentration, and the task is shared with less senior members of the crew. The OOW will also monitor the weather and if necessary re-calculate the optimum route accordingly. In tricky conditions such as a passage through a narrow strait or within a harbour, the master will personally take over.

The main body of the ship’s crew consists of Ordinary Seamen and Able Seamen (almost all males but the proportion who are females is rising), who help the deck officers by standing watch as helmsman or look-out, and carrying out the heavy work. There’s a lot to do, because in the competitive environment of commercial shipping, operating companies have reduced their crews to a minimum, perhaps as few as 20 or 30 hands to manage and control a vessel of 250 000 tonnes. The tasks often come in bursts, such as mooring the ship when it arrives in port at night, or helping to load and unload during a continuous 24-hour stint at the quayside. In between, the crew maintain and clean equipment as well as checking the cargo. The sea is an aggressive environment that will erode the hull structure over its relatively short lifetime of twenty years or so, and may weaken its resistance to wave forces. So the crew will spend much time washing salt water encrustations off the decks, scraping rusty steelwork, and re-painting the hull and deck plating.

The second main area of work has to do with the ship’s engines, and the master relies on the Chief Engineer to look after them and keep the vessel going. Unlike the deck crew, engine-room staff spend their time deep inside the hull where high temperatures and noise levels make demands on their stamina. Engineers are trained to improvise if necessary when things go wrong, because a breakdown can lead to expensive delays, while the loss of power in a storm can threaten the ship’s survival. The ship will carry spare parts to cover most eventualities, and working in confined spaces, the crew might have to replace a defective assembly weighing several tonnes in a very short time.

The third area relates to staff who look after the passengers and the remainder of the crew. On a passenger vessel, the Chief Steward supervises, instructing other personnel on daily duties such as cooking and serving meals, cleaning and maintenance, overseeing inventory, and ordering supplies. On a modern merchant ship, however, the cooks and stewards may answer to the Purser, the officer responsible for all administration including supplies together with the ship’s cargo and passenger manifests.

Working conditions

The conditions under which seafarers live and work are different from those on land. Junior crew stay on board for periods of up to a year, during which they might go ashore for a few hours at a time if at all [5]. The crew’s quarters are cramped with little privacy, and international standards permit seafarers to be on duty for 72 hours per week. Yet they are loyal to their ships, signing up for successive tours of duty with a closely-knit community in familiar surroundings. The ethnographic composition of the labour force and the process through which seafarers are recruited raise questions that are outside our scope, but you can find out more in [35]. The accounts of Professor Helen Sampson and others [4] [18] of the voyages they have made as passengers on commercial vessels are both compelling and disturbing.

A ship is a machine that needs constant attention. But in a heavy sea, it can pitch and roll in a way that hampers the crew’s ability to perform a simple task (figure 1). And the workload is uneven – on occasion the crew work continuously to keep the vessel safe, particularly when navigating into or out of port, when travelling in convoy along a canal, or weathering a storm. At such times, sleep seems to be a luxury, not helped by the fact that in bad weather, seafarers have to hold on to their bunks to avoid being tipped out onto the floor.

Figure 1

On board ship, the movements that affect people most are the vertical ones, and to a lesser extent, rolling motions about the ship’s longitudinal axis. What matters is not the distance moved, or even the speed of motion as such. This is because the human body doesn’t register a disturbance if it’s moving at a constant speed; rather, it’s the change in speed, in other words, the acceleration, that puts pressure on the limbs and upsets the balance mechanism of the inner ear. The motions of interest are almost all ‘periodic’ meaning that they oscillate through a more-or-less regular cycle. Subjectively, they divide into two categories. Lower frequency motions below 1 Hz are the ones that upset balance and cause seasickness. Movements that we normally think of as vibration occur at higher frequencies, and we’ll deal with these first.

Vibration

In a choppy seaway, the forces can be quite large. A planing vessel bumps along the wave crests like a horse-drawn carriage over cobblestones [39], and under storm conditions, any vessel can slam into a wave with sufficient impact to damage the hull. Other types of disturbance are less dramatic but cause discomfort for passengers and fatigue for the crew. A modern ship is a resonating steel drum vulnerable to disturbances that produce noise and vibration. Apart from wave impacts, the disturbances come from two main sources within the vessel itself: the engines and the propeller.

It’s worth looking a little more closely at the effect of the propeller. The thrust generated by each blade as it circles round the drive shaft is not constant – it rises and falls with every revolution as the blade passes through the uneven wake left behind by the hull. Earlier in Section M1410 we saw how the fluid particles arriving in the upper half of the propeller disk are affected by the hull boundary layer and their relatively sluggish movement results in momentarily greater thrust on a blade as it passes through the 12 o’clock position together with a shift in the effective line of action above the propeller centre. There’s another momentary peak in the thrust around the 3 o’clock position starboard of the shaft centreline owing to the angle at which the water meets the propeller disc.

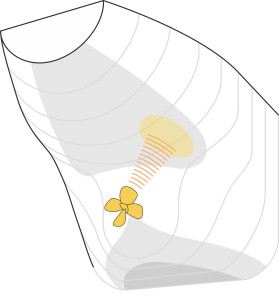

So the loading on a blade rises and falls during each revolution. This variation is transmitted to the ship in two ways, firstly through the propeller shaft itself, and secondly in the form of pressure waves transmitted through the surrounding water. Where the pressure waves meet the hull above, they cause the plating to vibrate. However, the amplitude is affected by another phenomenon: the propeller of a modern ship will cavitate before it reaches cruising speed, and the pressure waves generated by the cavitation bubbles as they collapse tend to dominate other sources [2]. As shown in figure 2, whether or not the propeller is cavitating, the resulting impact on the hull is concentrated almost in the plane of the propeller disk and, for a right-handed propeller somewhat to starboard [3]. This is why some mariners prefer cabins on the port side.

Figure 2

Vibration has long been a nuisance on ships large and small. However, the relationship between the input (vibration) and the output (its effects on humans) is not a simple one. The effect on passengers and crew depends partly on the duration of exposure, the frequency of oscillation (in reality it’s not a single value but a wide band or spectrum of frequencies), and the amplitude or intensity of the accelerations involved. The guidance set out in the current international standard [26] has undergone several revisions and since there is no single threshold that the designer can aim for, the results are not easy to interpret. In crude terms, after a few hours, a root-mean-square acceleration greater than 0.2 ms\(^{-2}\) will cause passengers to complain of discomfort, while a value greater than 0.5 ms\(^{-2}\) will cause fatigue and affect the crew’s performance [28].

Motion sickness

Low-frequency motions have a different effect. They arise mostly from sea waves, which cause the ship to heave, pitch and roll at frequencies typically in the region of 0.2 Hz, corresponding to a period of around 5 seconds. Humans are particularly sensitive to these oscillations – wallowing motions that many find acutely uncomfortable. However, not all react the same way: as explained in [19], some find the smallest movement intolerable, while others are scarcely affected. One can quantify the range of variation by plotting the percentage of people who experience discomfort at different exposure levels: the percentage appears to rise approximately in proportion to the root-mean-square acceleration. After 2 hours’ exposure to accelerations of the order of 0.5 ms\(^{-2}\) at a frequency in the critical range, it seems that a significant proportion of those on board – to put it crudely - will throw up.

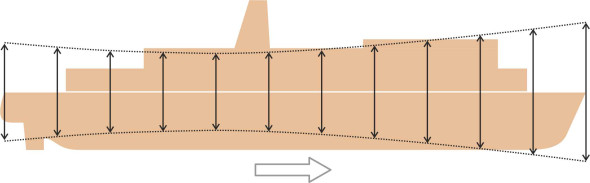

For decades, inventors have dreamed of inventing a new kind of ship in which people can sail without feeling ill. Of the many concepts put forward, most have failed. This is because conventional ships rely on buoyancy to support their weight, which means that they ride up and down with surface waves. But one can soften the impact by obtaining support from water further below the surface where the particle motions are less severe. This is the principle behind some radical hull configurations such as the hydrofoil, the SWATH, the wave-piercing catamaran, and the inverted bow. For a conventional displacement vessel, however, the options are limited. One possible solution is to install stabilising fins. Powered by hydraulic rams under computer control, they adjust themselves continuously to keep the ship more nearly upright in rough seas. While they may not greatly reduce motion sickness [20], they can make life aboard a little more dignified for cruise passengers by reducing the roll angle to a few degrees on either side while the ship is under way, and they make it easier for passengers and crew to sleep. For faster ships such as passenger ferries, the occupants benefit from windows that offer a view of the horizon together with headrests to discourage head movement [21]. Finally, as we saw earlier in Section M1115, the vertical motion of a ship varies along the length of the hull (figure 3), and if no other remedy is available, it may be possible to concentrate passenger facilities in the region where the amplitude is a minimum, at a point roughly two-thirds of the distance from the bow to the stern.

Figure 3

Cargo

Over the last century, the volume of sea traffic has grown considerably. There seem to be three reasons for this: first, the world population is rising, second, people are buying more goods, and third, the centres of production have moved away from the centres of consumption. Factories turning out retail goods have moved to the Far East, so countries like China now import materials from overseas to make finished goods, which in turn are exported all over the world. Manufacturing on this scale requires a continuous throughput, and by acting as a sort of conveyor belt, fleets of ships play an essential role in economic growth: about \(80\%\) by volume of all internationally traded merchandise is carried by sea [38].

Loading

To minimise costs, shipping companies arrange for their vessels to spend as little time as possible loading and unloading in port. During the 1950s, a ship spent longer at the quayside than it did at sea, because it took two weeks to discharge a typical cargo and take on a fresh consignment. Today, the process is much faster because vessels are designed to specialise in particular commodities, in units that can be handled using purpose-designed equipment.

Before it is loaded, a cargo ship resembles an empty biscuit tin – it is light enough to float almost on top of the water. But when fully laden, its displacement increases several times over. Whether or not it settles at the right angle of trim - and whether or not it remains stable and upright - depends on the way the load is distributed as well as the shape of the hull. Uneven placing can make the vessel capsize before it leaves the quayside, or even break in two. So, ship’s master prepares a plan showing where all the items are to be stored and the order in which they are loaded, and oversees the process using a laptop computer to log each one [33]. The master will then check the vessel’s trim and hydrostatic stability before putting to sea.

There are many different types of cargo. Some are liquids such as petroleum, while others are bulk solids such as iron ore. Some loads are mixed; protected in a crate or a sealed wrapping, each item is craned separately into the hold and wedged in place against its neighbours with packing material called dunnage – scrap timber, matting, or inflated plastic bags. As we’ll see shortly, mixed loads nowadays are more often packaged in containers. Containers hold a lot of air, so although they are bulky, they are relatively light in weight. This means that the number a ship can carry is limited only by the volume of storage space below and on deck - an example of a ‘volume-limited’ consignment. It also means that a container ship will float relatively high in the water, and may need ballast even when at full capacity. Other cargoes are relatively dense: the amount the ship can carry is determined by its total weight, even though there is empty space in the hold. A good example of a ‘weight-limited’ consignment is iron ore.

Uncomfortable cargo

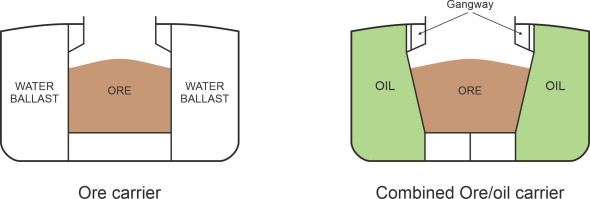

Iron ore consists of heavy lumps of rock. It doesn’t take much to reach the maximum load. The hold won’t be full, and because the ore settles at the bottom, it will drag the vessel’s centre of mass downwards towards the keel. In turn, a low centre of mass will affect the ship’s behaviour in a rough sea: it will be ‘stiff’ in roll, swinging like a pendulum with every passing wave, which can damage the masts and superstructure [9]. Equally important, the ore can make the ship unstable if it shifts from side to side. For this reason, a bulk carrier today is set up to carry the material in a specially configured hold. There are several ways of doing it, one of which is to divide the hull into three longitudinal compartments and use only the central compartment to carry the ore as shown in figure 4. The outer ones can be used as ballast tanks or to carry a less dense cargo such as oil; the combination raises the centre of mass to a more desirable position [11] [30].

Figure 4

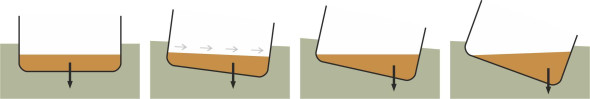

Loose cargo represents an appreciable risk, and over the centuries it has caused the loss of many vessels. If a liquid cargo has a ‘free surface’ it will surge from side to side when the ship rolls. You can experience the effect yourself by pouring some water into an empty tea tray (it only needs to be a few millimetres deep), and try to carry it across the room without spilling any. As shown in figure 5, the surge of liquid has a powerful destabilising effect, one that played a key part in the loss of the two passenger ferries mentioned earlier in Section M1818: the Herald of Free Enterprise and Estonia. Both capsized because water penetrated the bow doors and surged across the vehicle parking deck. The same can happen with granular materials, for example agricultural grain, which can move around and upset the ship’s balance [34]. Like bulk carriers, oil tankers and other liquid carriers can be made more stable by dividing the storage into longitudinal compartments. Today, a tanker may carry over 300 000 tonnes of crude oil divided between twenty or more tanks arranged arranged in groups of three or four side-by side [12] [37]. But oil presents other risks too, of which fire is the most obvious.

Figure 5

Fire and explosion together account for about a third of all ships lost [32]. Fire is widely feared by crews because it is difficult to escape from a burning ship, especially a tanker carrying oil or hazardous chemicals. In the confines of the hold or among closely-packed containers, the blaze may be difficult to suppress. You won’t be surprised to learn that strict procedures govern how such vessels operate, and over the last few decades, the risks have fallen greatly with the aid of a system originally developed by Sun Oil for pumping an inert gas into the hold of an oil tanker so the percentage of air falls to a level too low to support combustion - around 8%. The system was modified in the 1960s by the petroleum company BP and is now used world-wide [16]. Nevertheless, there have since been explosions on oil-carrying vessels belonging to a specific category known as OBOs (Oil-Bulk-Oil). They are caused by electrostatic discharges in tanks that have not been completely ‘inerted’ [8].

There are other kinds of inflammable material such as wool, which we don’t normally think of as a fire risk. Fertiliser poses a special threat. The most notorious case occurred in 1947 when a Liberty ship, the Grandcamp, caught fire in dock at Texas City while loading ammonium nitrate fertiliser: since firemen couldn’t put out the blaze, the ship was towed away from the harbour but it exploded before getting sufficiently clear, setting fire to a chemical plant near by, setting other ships ablaze, destroying the docks, and causing hundreds of fatalities on shore [24].

Finally, we must return to oil in connection with marine pollution. Although it happens less frequently nowadays, from time to time, a tanker will run aground and create an oil spill that contaminates many kilometres of coastline. Such events make headline news, but less widely appreciated is that during the Second World War, around 1500 tankers were sunk by enemy action. Together, they have been estimated to hold several million tonnes of ‘bunker fuel’ capable of devastating sea life. Nowadays, the cost of pumping out the oil from a wrecked tanker and cleaning up the spillage amounts to many thousands of US dollars per tonne [31].

Containers

Today, container vessels have changed the way many shipping companies operate. Although they make it more difficult for customs officers to check cross-border movements, sealed containers save time, reduce labour costs, and provide security against pilfering. Specially designed terminals enable them to be transferred between lorries, trains and ships relatively quickly (figure 6).

Figure 6

The container as we know it today was conceived by Malcolm McClean, who was engaged in long-distance road haulage between Houston and New York. The trucks were expensive to operate, and in 1956 he began experimenting with containers carried as deck cargo along a coastal sea route for part of the journey [7]. Nowadays, sea-going container freight is an industry in its own right. Currently, the largest operator is the Danish company Maersk. Its vessels carry retail items (for example clothes, bicycles and white goods) over fixed routes from China to Western Europe, a journey that takes around 20 days.

Containers are built to standard sizes so they can be transferred between different kinds of vehicle. The most common size is 20 ft long, 8 ft wide, and 8 ft 6 in high (\(6.06 \times 2.44 \times 2.59\) m). The empty box weighs 2.3 tonnes, and will carry a payload of up to 20 tonnes or thereabouts. So a loaded container is lighter than most cargos in relation to its external volume: \(22.3 \times 1000/ \left( 6.06 \times 2.44 \times 2.59 \right) = 676\) kg/m3 approximately, a little over half the density of water. However, until July 2016, the captain of a container ship could not accurately assess the total weight of the ship’s cargo because the containers were not weighed in port and the contents did not necessarily tally with the written manifest; hence they were frequently overloaded. In theory, port inspectors could open containers and check them against the paperwork, but in practice only a few were investigated and smuggling was not unknown. However, following a change in the regulations, shippers must now arrange for each container to be accurately weighed with the details set out in a formal document known as the Verified Gross Mass or VGM declaration.

Since they are relatively light in weight, containers can be stowed on deck as well as inside the hold, but there are disadvantages to this arrangement. First, the stack of containers on deck presents a large surface area to the atmosphere, which in a beam wind causes a significant heeling couple that reduces the margin of stability in roll; a container ship will slow down in heavy weather and sometimes arrive days late [23]. Second, although locked in place, the containers themselves are vulnerable to damage either from waves breaking over the gunwales or from heeling motions such as the parametric roll mentioned earlier in Section M1115 (figure 7). Some carry hazardous chemicals, and are checked regularly by the crew for damage and leaks; refrigerated units are inspected twice a day to ensure the cooling apparatus hasn’t broken down. Astonishly, some containers don’t arrive at all: they are lost overboard at a rate of more than 1000 a year worldwide [1].

Figure 7

Ballast

From time to time, a vessel will travel with little or no cargo at all, and will need handling just as carefully as it would if loaded. The hull rides high in the water, so the master will take on ballast. The weight of the ballast improves stability, and adjusts the trim so the propeller and rudder remain below the waterline. The ballast is a material that is both cheap and readily available to all ocean-going vessels: seawater. For a vessel with a double bottom, it’s usually carried between the inside and outside hull. A large vessel such as an oil tanker will need a lot of water, amounting to about \(30\%\) of the weight of its normal cargo [16]. When a ship arrives in port, it will discharge some or all of the ballast before taking on a new load. In total, ships are believed to transfer 5 billion tonnes of seawater annually from port to port in this manner, possibly affecting the marine ecology on a global scale. Depending on its origin, the ballast may contain alien plants, animals and micro-organisms from thousands of kilometres away. The IMO instituted a Ballast Water Management Scheme (BWM) Convention for new vessels in 2017, which was extended to existing vessels in 2019 (see the IMO website listed at the end of this Section [41]).

At sea

The sea has no boundaries: it covers two thirds of the Earth’s surface and there are no direction signs or road markings so there is plenty of room to sail around without seeing another ship all day. But that’s only in mid-ocean. Closer to shore, there are busy waterways, and only a few decades ago, collisions in coastal waters were common. Because of growing congestion, maritime authorities installed a range of measures intended to reduce the frequency of accidents. In addition to the existing buoys that marked safe routes through shallow waters, there came into being a VHF radio network through which ships could communicate with each other and with the coastal authorities on shore. In addition, shore-based control systems were installed to monitor individual movements. Nowadays, each voyage takes place within a blizzard of digital information, partly based on communications satellites, and partly on ship-borne information technology. As a result, the process of navigation has changed in ways that past generations of seafarers could not have imagined.

Communication

Ships that meet on potentially conflicting paths need to communicate with one another so that each master is clear what the other intends to do. The rules for determining which vessel has right of way, and for taking action to avoid a collision, were outlined in the previous Section. Here, we’ll concentrate on the communication process that accompanies the manoeuvres. A hundred years ago, most vessels used flags and signalling lamps to exchange information; they have since been replaced with horns and lights. Interestingly, in 1912 Fressenden developed a method for underwater communication using Morse code [27], but as far as I’m aware it has never been in widespread use. None of these methods works well in fog because if there are more than two vessels in the area it may not be clear who is trying to communicate with whom.

Other devices have emerged during the last century that don’t rely on vision or sound. The first is an Automated Identification Systems (AIS) that is carried by all ships over 300 gross registered tonnes [13]. Transmitting over VHF radio, its function is to signal the ship’s identity both to other vessels nearby and to coastal authorities on shore. It has a range of 20-30 miles, and displays not only the vessel’s identity, but its position, heading, and speed, together with details of the voyage being undertaken. Among other things, the system gives advance warning to other vessels of its arrival, and enables onshore control stations to track its progress and ensure a safe passage through busy areas. But if two ships are on a collision course, AIS doesn’t sort out which should give way. In principle the respective masters can use an audio VHF channel to negotiate, but this is not altogether foolproof. Strangers can misunderstand one another, and if the ships are on a collision course, they need to decide quickly what to do. As reported in the UK government Marine Guidance Note no 167, the judge in a collision case said in 1995:

‘It is very probable that the use of VHF radio for conversation between these ships was a contributory cause of this collision, if only because it distracted the officers on watch from paying careful attention to their radar… any attempt to use VHF to agree the manner of passing is fraught with the danger of misunderstanding.’

It’s in these circumstances that a clearcut rule-based procedure works best, which is the purpose of the collision avoidance rules that we mentioned earlier in Section M0415. The procedure requires only visual observation supplemented by radar, with horn signals to indicate the master’s intentions in cases of doubt.

Traffic control

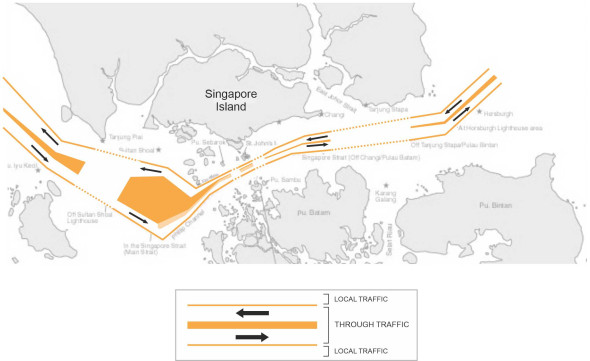

In a busy channel, it is possible to reduce the risk of collision and speed up traffic by organising the flow into notional shipping lanes. Vessels intending to pass non-stop through the channel are marshalled into two streams running in opposite directions on either side of the channel centreline, just like a motorway. Local traffic such as coastal vessels and those crossing the channel will travel closer to shore. So there are three notional lines of separation as shown in figure 8: a central separation zone that divides the two directions of ‘through’ traffic, and (b) two marginal separation lines, one on each side, that separate the through traffic from local traffic [15]. All three lines are notional in the sense that there are no buoys marking their presence on the water: they exist only on charts. However, many such schemes are recognised internationally by the IMO. Presumably the biggest problem with systems of this kind arises from crossing traffic. A vessel on a local trip between opposite shores is advised to cross at an angle as close as possible to \(90^{\circ}\), while a vessel wishing to join or leave a ‘through’ route is advised to do so do so at a shallow angle in order to make its intentions clear in good time to any other vessel nearby.

Figure 8

The first internationally recognised traffic separation scheme was installed in 1979 in the Dover Strait, at that time the world’s busiest waterway. Previously, the area had suffered an average of 30 collisions per year, but since the scheme was introduced, the rate fell to zero [17]. Today there are many other schemes in operation, for example at Singapore, around Cape Horn, in the German Bight, and at other locations in the Mediterranean and along the west side of the Atlantic and Pacific. Figure 8 is a simplified representation of the system that operates along the south side of Singapore Island. The gaps in the separation lines are places where ships frequently turn into and out of other channels along the route.

Navigation

During family walks, when my children were small they used to ride their bicycles along the footway ahead. They didn’t know the layout of the streets, and they couldn’t say which compass direction they were travelling in, but they knew the way, using features of the landscape as serial cues to remind them where they were and where to go next. At one time, this was how seafarers used to navigate. As long as they could see the coastline, they could use familiar landmarks to establish their position. Ocean crossings were more difficult. Once out of sight of land, there was very little to go on, and it took many centuries for mariners to develop the tools needed for long-distance navigation.

Chief among them were charts showing the port of destination in relation to the port of origin. A chart of some kind was needed on which one could plot the ship’s course - you may recall that in Section M0415 we mentioned different types of course such as ‘rhumb line sailing’ and ‘great circle routes’. Crucially, there was a compass for pointing the ship in the right direction, then there were devices for checking the ship’s position at each stage of the journey, including a chronometer, a sextant for determining latitude, and a ‘lead and line’ for measuring the vessel’s speed, and finally, a nautical almanac, tide tables, and to help with the calculations, a set of mathematical tables.

The position today is changing. On a large ship, mavigation is usually the responsibility of the Second Officer, the third-ranking deck officer on board. It’s not our intention to go into the subject here, the details of which you can find in the standard textbooks, for example [10] and [25]. Instead, we’ll break down the task into its main components using non-technical language, and see what changes are taking place under the influence of recent developments in information technology such as GPS (the satellite-based Global Positioning System), electronic charts, automatic gyro-stabilised radar plotting devices, and other ship-borne aids.

Assume we are intending to travel from port A to port B, whose locations are both known. One can picture the navigation process as a collection of tasks:

- Planning: plotting a route

- Course keeping: adjusting the ship’s course and speed as necessary

- Manoeuvring: avoiding collisions with other vessels, and with obstructions along the route, also negotiating straits and canals

- Landfall: Navigating the approach to the destination port and mooring at the selected berth

- Position-finding.

The fifth task, position-finding, overlaps all the others, and in some ways it’s the most important. In mid-ocean, the navigator carries out precise astronomical measurements and uses the principles of trigonometry to establish latitude and longitude in the absence of familiar landmarks. When available, bearings obtained from shore-based radio stations help to fix the ship’s position. Until recently, the work was done by hand, at regular intervals throughout the voyage. As well as being a heavy responsibility, the process carried a certain mystique, perhaps because the geometry was expressed in an archaic mathematical language: your author has a little book on navigation, written about fifty years ago, that refers to obscure trigonometric functions, log tables, and even to the signs of the Zodiac and their historical origins (they were used to help the reader to identify important star constellations). It seems a long way from what happens today, now that GPS is universally available to travellers to determine their position almost instantly and with very little effort.

GPS may have resolved the position-finding issue, but the other tasks remain. We’ve already referred to route planning in Section M0415, where we briefly compared the merits of rhumb-line sailing and great circle routes. The great circle route is always shorter, but the saving is not large unless the ship is engaged on a long voyage, for example, across the Pacific Ocean, a journey that will take a cargo vessel around 5 weeks. In theory, a great circle route requires the helmsman to steer a compass direction that changes continuously throughout the voyage. In practice, the navigation officer will break the route down into smaller segments and work out a fixed course for each segment treated as a rhumb line. On some ships, it is possible to automate the process, with the ship’s steering linked to the gyrocompass and an electronic chart system.

Dealing with the unexpected

However, there are other factors to be taken into account. While a great circle route may be the shortest route, in practice in may not be the quickest if it plunges the vessel into bad weather. At sea, bad weather has two consequences. First, it slows the ship down because its resistance to motion increases roughly as the square of wave height. Second, to avoid damage to the hull (and to avoid being inundated) the master may decide to change course and steer into the oncoming swell. Hence when planning a voyage, mariners tend to avoid areas where storms are likely to occur, a practice sometimes called ‘climatic routeing’. Nowadays it is possible to take this a step further. Supercomputers have enabled meteorologists to simulate the earth’s atmosphere in greater detail, and hence to produce more accurate weather forecasts typically five days in advance, together with predictions of the significant wave height. On this basis, the navigator can take account of local weather variations over time as distinct from average variations from place to place. As a result, vessels are switching to a new strategy: ‘weather sailing’, in which computer-based predictions of wave characteristics are used to optimise the route. It is thought to yield a \(5\%\) saving in journey time.

Other events can arise that are difficult to forecast – unexpected sources of delay such as a mechanical breakdown, illness, a person overboard, or a traffic queue at the port of destination (readers will recall the case of the Ever Given container vessel that ran aground in the Suez Canal on 23 March 2021 and blocked the waterway for nearly six days - the blockage held up more than 400 vessels until the ship was freed). Finally, although it doesn’t happen very often, the radio operator may pick up an SOS message. There is a long-standing tradition among seafarers that in such an event, they will go to help any vessel that has run into difficulties, a tradition that is enshrined in Regulation 33.1 of the SOLAS (Safety of Life At Sea) convention: ‘The master of a ship at sea … on receiving a signal from any source that persons are in distress at sea, is bound to proceed with all speed to their assistance…’.

Landfall

We’ve already mentioned that during a voyage, the greatest risks tend to occur close to the shoreline, partly because of the flow of traffic on conflicting paths, and partly because of the shallow water. On the approach to a port or harbour there is usually a channel deep enough to accommodate a large ship, and its path is marked by two lines of buoys, one on either side. A buoy is a floating canister anchored to the seabed via a chain and a heavy weight so it will stay in place, although the profile of the seabed changes from season to season and buoys are sometimes moved accordingly. Each vessel stays close to the line of buoys on the starboard side, as if driving on the right hand side of a motorway. These particular buoys are called ‘lateral marks’. In addition, there are other types of buoy that indicate, for example, hazards such as a submerged wreck.

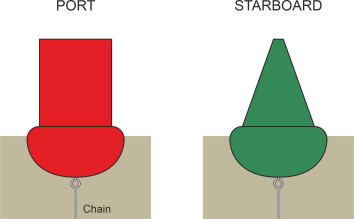

Buoys that act as lateral marks are made in two basic shapes. Although the details vary from place to place, an upright cylinder marks the port side, and a cone the starboard side, as shown in figure 9. Of course, this distinction holds only for ships travelling in one particular direction. By convention, the ‘direction’ points towards land, meaning that for a river estuary it points upstream, and for a harbour, it points towards the entrance. When a vessel arrives, the conical buoys lie on its starboard side, but when it leaves they are on its port side. To assist identification, the buoys are painted in different colours. There are two distinct colour conventions that apply in different parts of the world. Coastlines around the continents of North America and South America together with Japan, Korea and the Philippines have adopted ‘system B’. Everywhere else uses system A [14]. In system A, the port side buoys are painted red while starboard buoys are painted green; in system B, the shapes are the same but the colours are the other way about.

Figure 9

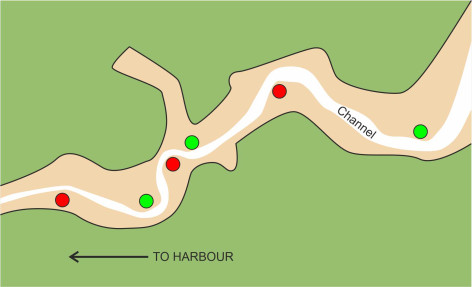

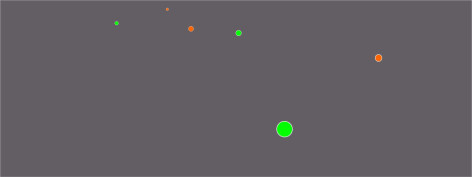

If anything, buoys are more important at night than they are during the daytime. Many carry flashing lights. Figure 10 is a simplified view of the buoys that delineate part of the Thames Estuary near London. The coloured circles represent buoys with lights. They follow system A, in which the port buoys have red lights while the starboard buoys have green ones. When a ship approaches at night, the Officer of the Watch sees an array of lights blinking in the distance that to appear to be scattered at random along the horizon and can easily be confused with city lights on shore. Interpreting them requires practice, and a merchant sea cadet’s training course will include a session on a computer simulator that displays the lights against a dark background. Figure 11 shows how the system for the river estuary in figure 10 might look from a ship’s bridge. In reality, there would be other types of navigation light in the vicinity together with the lights of other vessels nearby, all of which make it more difficult for the bridge crew to interpret their surroundings and pick out a safe course. Hence the captain of a larger ship will take on a pilot who is familiar with the layout. As described in the preceding Section, at the end of the voyage, the final manoeuvre – docking at the pre-arranged berth – requires special attention, and will be carried out slowly to avoid damaging the ship or the quayside. It’s not the end of the story, because the Master and many of the crew will stay on board to monitor the discharging of cargo and re-loading for the next trip.

Figure 10

Figure 11

Closure

As you read this, thousands of ships are plying the ocean, including 50,000 merchant vessels that operate a global merry-go-round, ferrying materials and retail goods from country to country in response to the forces of demand and supply. Each carries an automated VHF radio system that sends out a message every few seconds to signal the ship’s identity. You can log into a web site and track its progress [40]. The web site will tell you the ship’s name and what flag it is sailing under, its speed and course, and other details from which you can piece together what the vessel is doing and why. A few are carrying passengers, but most are loaded with food, clothing, fuel, goods and raw materials. Unremarked and almost invisible to people on shore, they form a supply chain without which the world’s economic system would quickly disintegrate. It’s a competitive business and the pressure is unrelenting. If you include the crew’s wages, fuel, maintenance, insurance, and capital depreciation, the cost of running a ship may run into hundreds of thousands of dollars per day. So the vessel must earn its keep: the sooner it can reach it destination port and and turn around for the next trip, the more goods or passengers it can carry and the greater the return on capital investment.

In this series, we have drawn attention to the way ships move. Ships are efficient because of the physical nature of the medium in which they travel. Water is dense, so the fluid itself can carry a large weight spread over the hull surface. On the other hand, water resists motion. Given a suitable route over land, a lorry or a train would be quicker, but paradoxically, if the ship doesn’t need to go fast, the resistance almost vanishes. So a merchant vessel usually sets out at a modest speed, often taking weeks to reach its destination. This ability to carry hundreds of thousands of tonnes of cargo, slowly but more efficiently than by any other means of transport, is what sets marine vehicles apart.

But for ships, slow doesn’t necessarily mean safe. Worldwide, significant numbers of merchant seafarers are killed each year; most are sailing under a ‘flag of convenience’, and the data are inconsistent and difficult to access [36]. Yet many people choose to work on ships, a high proportion of whom come from developing countries where the prospect of higher wages seems to compensate for long periods away from home. For others, the sea exerts a powerful fascination: we know that in past centuries, driven by curiosity or seeking freedom perhaps, young men abandoned their homes and families to join a ship bound for the other side of the world, and today, a few women are signing on too.

Figure 12

Acknowledgements

Photo on opening page: British naval destroyer HMS Thruster rolling in heavy seas off Alexandria, photo originally appearing in WINCHESTER, C (ca 1936) Shipping wonders of the world. London: Amalgamated Press, p822.

Figure 06: Mayview Maersk and OOCL Tianjin at the EUROGATE Container Terminal at Wilhelmshaven, http://www1.eurogate.de/en/About-us/Press/Photo-service, accessed 08 May 2018, by kind permission of Eurogate.

Figure 07 Photo by courtesy of the Momentum Shipping Lounge, Monthly Archives, May 2017: http://www.momentumshipping.net/lounge/wp-content/uploads/2017/05/damage4.jpg, accessed 05 October 2017.

Figure 11 The traffic separation scheme at Singapore: image at https://www.imo.org/en/OurWork/Safety/Pages/ShipsRouteing.aspx, by courtesy of the International Maritime Organisation (IMO), May 2021.

Figure 12: Lino cut by Penelope Wright ‘The owl and the pussycat’ (from the nonsense poem by Edward Lear, 1871).