© skystef

G.2020

Welcome

Welcome to the Contact Patch. In this web site, we’ll be looking at transport in a new way. Everywhere, vehicles are on the move, carrying people and goods from place to place at a rate that would have been impossible only a century ago. Each vehicle is in physical contact with its surroundings: a road vehicle is carried on pneumatic tyres pressing on the road surface, while a train rolls along a steel track (figure 1). In contrast, a ship is supported by the water underneath its hull, and an aircraft by the air flowing over its wings. Usually, the weight carried by each wheel of a land vehicle is transmitted to the ground through a small ‘contact patch’, while ships and aircraft spread their weight over a much larger area. And all are exposed to aerodynamic forces that can slow the vehicle down or carry it off-course.

Figure 1

So what happens at the interface? Imagine you are in a car cruising along a motorway at 120 km/h, and picture a small section of the tyre tread on one of the front wheels. You might expect that when it enters the contact patch and presses on the road surface, the tread and the road surface are momentarily locked together so there is no slippage, no relative motion. Elsewhere, it would appear that air is rushing past the vehicle, sliding over the bodywork at around 120 km/h. But this is not what happens. Paradoxically, it’s the other way around. The tyre tread creeps over the road surface, while as far as anyone has been able to determine, the layer of air closest to the vehicle does not slide past at all, but is carried along with the vehicle as if glued to the body surface.

Aims

Fortunately, the rate of creep within the contact patch is small, and the layer of air carried along with the body surface – known as the ‘boundary layer’ – is thin. But both play a significant role in vehicle dynamics, and in what follows we shall spend some time looking at the different kinds of interface and the forces they convey, which (a) support the vehicle’s weight, (b) control its direction of motion, and (c) determine the resistance that the engine must overcome. We shall also be looking at the converse problem, which is the impact of the vehicle’s motion on its surroundings together with the traces it leaves behind. In short, we are dealing with transport technology from the ground up.

The web site is a work in progress. At the time of launch in 2013, it consisted of nineteen Sections, some dealing with road vehicles and others with more general matters. Since then, the content has grown to include railway vehicles and ships together with a review of fluid mechanics as applied to vehicle motion. The process has taken longer than anticipated, and we expect the final tranche on aircraft flight to be uploaded in 2022. Some of the content is new, though most is adapted from books and papers published by other writers, and is therefore second-hand. To the extent that many of the sources are themselves are re-workings of other people’s material, it is third-hand. We are building on the work of others. This is inevitable because transport engineering spans across a number of disciplines and no-one can be expert in them all. Our excuse, if we need one, is (a) that not all the topics are easily available in published form, and (b) some kind of overview might be useful. And from time to time we do attempt to tie up loose ends (such as the ‘correct’ alignment of the Ackermann steering linkage that connects a car’s front wheels), or to re-interpret an obscure topic in a way that the newcomer can more easily understand.

Content

We’ll be delving into the mechanical sciences with a dash of physics and chemistry, and where necessary we’ll use mathematical equations to help explain what is going on. Engineers use mathematics because they have to quantify things in order to make things work. But the maths needs a foundation to build on, namely an intuitive understanding of the phenomena one is trying to describe. This entails thinking in pictures – mental images that are unique to every individual. After all, physical phenomena can be understood at different levels, no one of which tells the whole story.

A good example is what makes an aircraft fly (figure 2). There are at least six different explanations, and scientists are not entirely happy with any of them [1]. One of the simplest is that the wings deflect the air downward, and the force they apply to the air creates an equal and opposite reaction that we call ‘lift’. But how to explain the deflection – why does the air go down rather than up? Here, we’ll focus on the role played by friction, which leads to a curious asymmetry in the flow above and below the wing surface.

Figure 2

Another would be the rolling resistance that slows down a railway train, some of which arises because the track is not completely rigid. You can tackle this either (a) by writing down equations for the energy that dissipated in the ground beneath as it deforms under the weight of the vehicle, or (b) by painting a simple mind-picture: the track sags beneath each wheel and the depression is dragged along, a little behind the wheel because the ground is sticky and takes a moment to recover. The wheel is therefore travelling uphill. Even if you can’t predict the forces involved, at least you can make sense of what happening. If the maths doesn’t work for you, the pictures might.

Structure

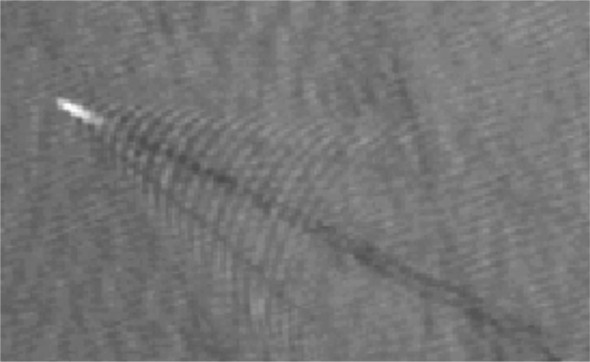

The web site covers four modes of transport: road, rail, water, and air. Within each mode, the material is divided into Sections, each numbered with a prefix to indicate the mode to which it belongs. The prefix C denotes roads together with the vehicles that travel on them such as cars, while R denotes railways and railway trains, M stands for marine craft, and A for aircraft. There are also two areas that span across all the transport modes. In the first area, all Sections carry the prefix G; they deal with vehicle dynamics and a number of general topics relevant to most vehicle types. Those in the second carry the prefix F, because they relate to fluid mechanics, again an area that spans across all modes, and a rich area of study in its own right (figure 3).

Figure 3

Each Section title (for example R0418 Hunting) contains a number that reflects its position within a notional structure. Like the roots of a tree, the topics divide and subdivide as they penetrate into the soil beneath. Topics located high on the stem are concerned with the vehicle as a whole, while those lower down have to do with matters of detail. In fact there are really two kinds of root. The first kind relates to hardware: the mechanisms and materials that make up a working vehicle (figure 4). The other relates to principles, specifically, those that govern how objects behave.

Figure 4

How to use the site

The structure is not particularly important because the topics are self-contained. You can dip into them at random, or if you prefer, tackle them in the order in which they are set out. We start at the bottom, not the top, that is to say, we start with the contact patch and work upwards in stages to the behaviour of the vehicle as a whole.

Within limits, you are welcome to use the material for your own purposes. This includes the text and the diagrams, which are copyright under the Creative Commons framework. This means you can download them, copy them into your own documents and change them if you want. But please acknowledge where they came from and don’t use them commercially for gain of any kind. The photographic images are copyright under a different arrangement, and you must contact the owners separately for details.

As explained earlier, most of the material in this web site is a re-interpretation of material produced by other people. There is always a risk of mistakes, so please don’t take anything you read here for granted. There are plenty of mistakes (or misrepresentations) in what follows. It’s just that we don’t know where they are yet. If you find some, please let us know. We would greatly welcome your comments, criticisms and suggestion for improving the site. Please email christopherwright1944@gmail.com.

Production

Web realisation by Tom Wright: Tom is a developer and occasional photographer with nearly two decades under his belt building experiences for the web, helping people from small independent local businesses all the way up to FTSE100 companies find their place on the internet. Email: tom@inflatablecookie.com.Layout by James Wright: James is a Graphic Designer and Art Director whose clients have ranged from blue chip corporations to boutique start-ups in fields as diverse as art, music, finance, and consumer goods. With over 20 years’ experience of branding, packaging and experiential projects he continues to help individuals and brands communicate through innovative design. Email: jamesmwright@me.com.

Diagrams and text by Chris Wright: Chris is Emeritus Professor of Transport Management, Middlesex University, London. Originally trained as a civil engineer, for the last 50 years he has specialised in transport research, serving at various times as chairman of the Executive Committee of the (UK) Universities Transport Study Group, and as a member of several professional committees including the editorial board of the Municipal Engineer. He has advised the London Assembly on aspects of the Mayor’s transport policy, has appeared on a number of radio and TV programmes, and produced over 150 research papers in the transport field. Any errors or omissions are his responsibility. Email: christopherwright1944@gmail.com.

Photographic images by Susanna Rosti Rossini: Susanna is a professional artist photographer and lives in Florence. She has studied interior architecture specialising in lighting design, and is passionate about jazz piano. These interests bring two distinctive qualities to her photographic work: a sense of balance in visual composition that is reflected in the juxtaposition of light and shade, and a dynamic flow of image material. Concentrating mostly on landscape, nature, and abstract subjects, she has exhibited in Milan, Amsterdam, Genoa, London, Faversham, Whitstable, and Florence, and has been awarded grants by the Wandsworth Arts Council and published four photography books, which you can browse at https://www.bobbooks.co.uk/bookshop/search/term/susimagin. In 2019 Susanna won the first prize at the competition ’Premio Pittura Panzano’ in the Chianti region in Tuscany. Susanna’s web site is at www.susimagin.com; email susimagin@gmail.com.

Paintings of camper van and ‘The Owl and the Pussycat’ by Penny Wright: Penny has a BA in Graphic Fine Art from KIAD, and works as a print-maker and multi-media artist. She makes artist’s books and illustrates for children of all ages. Email: moonmamamail@gmail.com.

Other photos by Barry Duffield, Joanna Walpole and Tom Wright

Acknowledgements

The author is grateful to Chris Abbess and Dr Patricia Wackrill for many helpful discussions that have contributed directly and indirectly to the preparation of this web site; Prof Oliver Carsten, Institute for Transport Studies, University of Leeds, for advice on safety matters; John Elliott, Consultant, for encouragement together with constructive suggestions; B Ferne, Transport Research Laboratory; Professor Simon Inwicki; Malcolm Macdonald, Head of Vehicle Restraint Systems, Transport Research Laboratory; Duncan MacIntyre; Dr C G B Mitchell, formerly Transport Research Laboratory, for helpful pointers to do with bus ride quality; Dave Skirrow, Training and Standards Manager, Stagecoach Supertram, Sheffield for useful discussions and documentary material; James Snowdon, Chief Engineer of Tramtrack Croydon for helpful discussions on tram technology; Richard Woods, Workshop Manager of the Gist depot at Faversham, for explaining the ins and outs of freight vehicle maintenance; and to Linda Thomas and Margaret Wright for their patient and meticulous efforts in proof-reading and correcting material; and the library staff of Middlesex University and Kent County Council for their kindness and help throughout. Finally, I would like to acknowledge as the inspiration for this web site my father Frank Wright, who died in 2003.Pictures featured in this Section

Photo on opening page: posted on Skystef’s Aviation Page at http://www.skystef.be/contrail-special.htm and accessed 18 May 2021, reproduced by kind permission of the site owner.Figure 1: Wheel and axle unit for a steam railway engine (Photo by kind permission of Barry Duffield Photography).

Figure 2: Tiger Moth biplane (photo by kind permission of Barry Duffield Photography).

Figure 3: Satellite photo appearing in ERCIM (European Research Consortium for Informatics and Mathematics) NEWS 108 January 2017, Special theme: ‘Processing satellite imagery to detect and identify non-collaborative vessels’ by Marco Reggiannini and Marco Righi (ISTI-CNR), https://ercim-news.ercim.eu/en108/special/processing-satellite-imagery-to-detect-and-identify-non-collaborative-vessels, copyright Marco Reggiannini and Marco Righi and posted under Creative Commons Attribution 4.0 International License (CC-BY), accessed 20 November 2019.

Figure 4: Lady with bicycle (photo by kind permission of Barry Duffield Photography).

14 July 2021