G.1615

Bearings

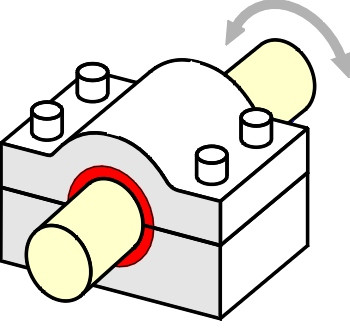

Vehicles are built from many parts. Some of the parts move relative to their neighbours, and the surfaces press and slide against one another where they come into contact. For example, each wheel on a horse-drawn cart rotates around a fixed axle. The centre of the wheel is bored out to a smooth finish and the axle stub (likewise machined to a smooth finish) fits inside but not too tightly so the wheel can revolve freely. This configuration is often reversed. For example, if the wheel is driven by an engine, the axle rotates inside a fixed sleeve (figure 1). In either case, although they are only a few square centimetres in area, the bearing surfaces carry the whole weight of the vehicle together with its payload and must therefore withstand high stresses. Because they are hidden from view we tend not to notice them, but bearings produce friction, sometimes overheat, and eventually wear out. Bearing failure can halt a machine and possibly lead to catastrophe if the surfaces fuse together or disintegrate. That is why bearings are in many cases the most vulnerable parts, and the most expensive to make. It also explains why the study of friction between moving surfaces has become a subject in its own right, known as tribology after the Greek word meaning to rub. We shall only (no pun intended) scratch the surface here.

Figure 1

Plain bearings

Most bearings are plain bearings, otherwise known as ‘journals’ or sleeve bearings. The two mating surfaces are machined to fit together, which guarantees a large contact area and in turn helps to spread the load. Plain bearings are particularly suitable for slow-moving machinery, or for shafts that must carry heavy loads, especially impact loads of the sort experienced by a diesel engine crankshaft under the hammering of the pistons.

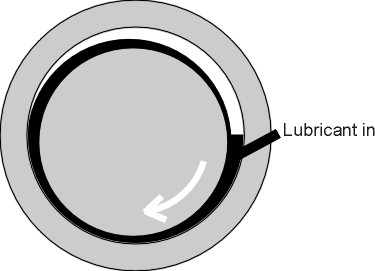

If you’re new to the subject you might be surprised - like I was - to discover that when a bearing is working properly there is no metal-to-metal contact at all. A thin lubricating film prevents the surfaces from grinding against one another. In some cases, the fluid is pumped into the bearing under pressure via holes and channels. Others rely on the rotating shaft to drag a thin wedge of lubricant into the region where high pressure is needed to keep the surfaces apart (figure 2), a process that in some ways resembles the aqua-planing of a tyre on a wet road surface (see Section C1603). In fact, a lubricant can withstand extremely large forces, its resistance increasing as the film is squeezed to just a few molecules thick, as it is for example in the high-impact contacts between the teeth in a vehicle gearbox. Provided one can keep out dirt, grit and particles of worn metal away from the bearing surface, a lubricant will last almost indefinitely.

Figure 2

On the other hand, a lubricating film can break down when the movement ceases and the fluid is squeezed out. For example, when a car engine is switched off and left to cool, the crankshaft settles and the bearing surfaces come into contact. Hence most of the wear that afflicts a car engine will occur during the first few seconds of a journey, after the engine is started up and the bearings are running dry [3]. It follows that a plain bearing is not ideal for vehicles that are continually starting and stopping. During the 19th century, hundreds of thousands of rail wagons were built with plain bearings, each contained inside an axle-box that provided lubrication. They were the most vulnerable part of a moving train, and smoking or seized axle-boxes were a daily occurrence [2].

Ball bearings

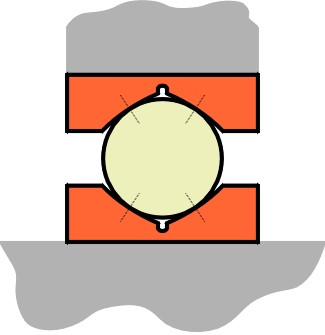

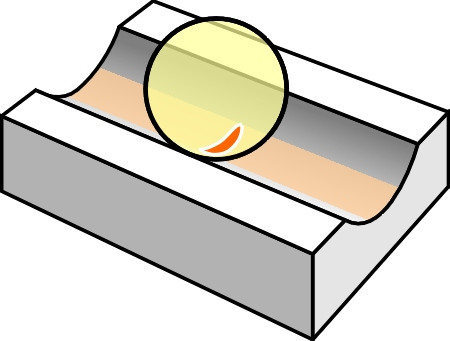

A set of ball bearings, sometimes called a ‘ball race’, does away with sliding contact because the surfaces roll past one another. The inner and outer bearing surfaces are called raceways, and they are machined with grooves which keep the ball bearings in place. In principle, the grooves can be ‘V’-shaped so that each ball touches each raceway at two separate points (figure 3), but in most cases the cross-section of each raceway is a circular arc (details of some of the most common varieties are set out in [4]). The radius of the groove is just a few percent larger than the radius of the ball so that the load is spread over an appreciable area, which after bedding in, becomes roughly elliptical in shape perhaps a couple of millimeters wide by a fraction of a millimetre in the direction of rolling (figure 4).

Figure 3

Figure 4

Even though the load is spread in this way, the normal stress may still be around 1500 N/mm2 or more [5], a value that is roughly equivalent to the stress generated by two grown men standing on a sugar crystal. Under these conditions, the crystal – whether it be made of sugar or steel - would shatter. In a ball bearing, the ball and raceway survive because the contact areas are supported by the surrounding mass of material, in which the stress falls rapidly with distance away from the contact centre. As a result, bearings rarely break in the way that an axle might, for example: failures tend to be surface failures in which the material becomes grooved or pitted.

It is a curious feature of surface contact that the greatest shear stresses tend to occur not at the surfaces themselves but some way below the surface, so the material in a steel ball or raceway can undergo plastic deformation while the surface remains intact, rather like the yolk in a soft-boiled egg. The critical depth is equal roughly to a quarter of the smallest diameter of the contact patch. This is why procedures such as ‘case hardening’ that are designed to strengthen bearing surfaces must be capable of penetrating to an appreciable depth [6].

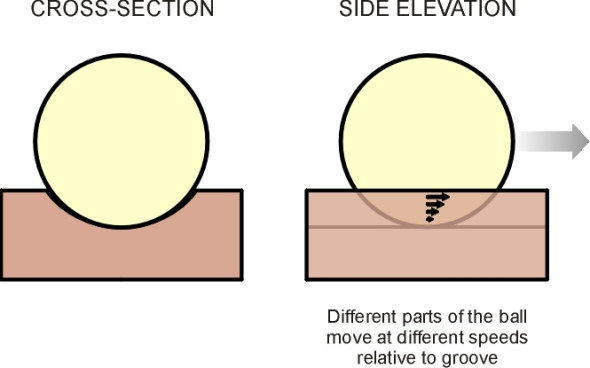

It’s important too that the balls are precisely machined to the same size otherwise they will carry unequal loads and orbit at unequal speeds, bumping into one another and producing excessive friction and wear. Good quality ball bearings contain cages or races to keep them apart. Because of the rolling action, lubrication is less important for ball bearings than it is for journal bearings, and they can operate at higher speeds. However, if we look closely at the surface of any given ball, we see that different parts of the surface that are in contact with the raceway move at slightly different speeds because they are located at slightly different radii from the axis of rotation (figure 5). Hence although it is greatly reduced, ball bearings still create some friction through sliding or creep [1]. And as with any rolling wheel, repeated loading and unloading also leads to a small rate of energy loss through hysteresis (see Section G1619).

Figure 5

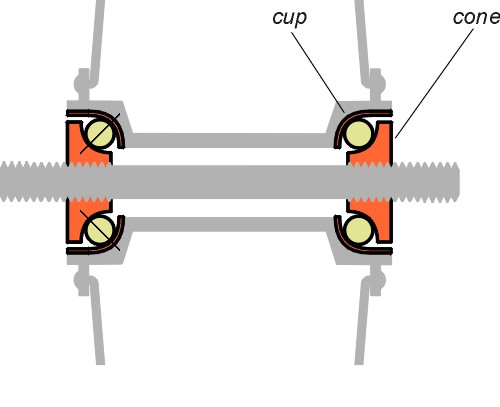

Although they generate little friction, ball-bearings have two significant drawbacks. Firstly, on its own, a single ball race can carry a load only if the load acts radially, at right-angles to the shaft. It’s not much good at dealing with axial forces of the sort that occur when a wheeled vehicle travels round a bend. So for many years, car wheels were equipped with two ball races, with the raceways angled in the same way as the cup and cone races of a bicycle wheel (figure 6). Secondly, because the contact area is relatively small, the maximum load in any direction is limited.

Figure 6

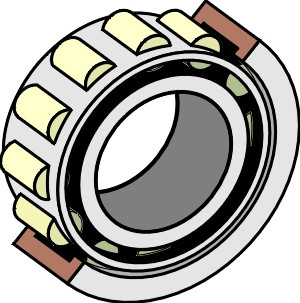

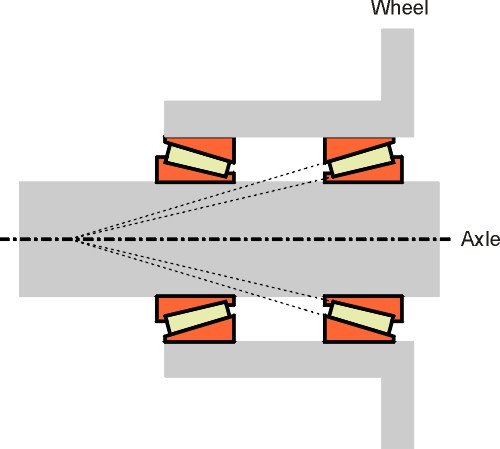

Roller bearings

By contrast, roller bearings are more robust. Each roller presses against the inner and outer raceway nominally over a line of contact rather than a single point, so it can carry a heavier load (figure 7). Again, roller bearings are often used in pairs on car wheels, each angled so it can deal with axial forces. To ensure there is no sliding contact, the rollers must be tapered as shown in figure 8. Car wheels are packed with lithium-based grease, and sealed for life with a radial ‘lip seal’ that is spring-loaded to maintain light rubbing contact [7]. In the case of railways, roller bearings have universally replaced plain bearings in some countries, but they don’t smoke or otherwise give warning before they fail [2].

Figure 7

Figure 8

Conclusion

Rather like car tyres, ball bearings and roller bearings have developed gradually through a series of small improvements in the materials from which they are made, and the method of manufacture. They are now cheap, robust and reliable. Most continue to work in the same way that they did in Victorian times, relying on contact between hard surfaces with a lubricant to reduce friction and wear. However, other types are available for special purposes that involve no contact at all. Instead, the components are separated by a repulsive field of some kind. Magnetic bearings hold the spindle steady in a magnetic field. In a gas bearing, the moving surfaces are separated by a gas film that is forced under pressure into the gap. Both have indefinitely long life and reduce friction to miniscule levels, a feature that makes them useful for special functions such as navigation gyroscopes and energy storage flywheels, which could in future be used for regenerative braking in transport vehicles.

Revised 11 February 2015